IPEC PD Detector Pro

Brand :

IPEC

Categories :

Partial Discharge Spot Testers

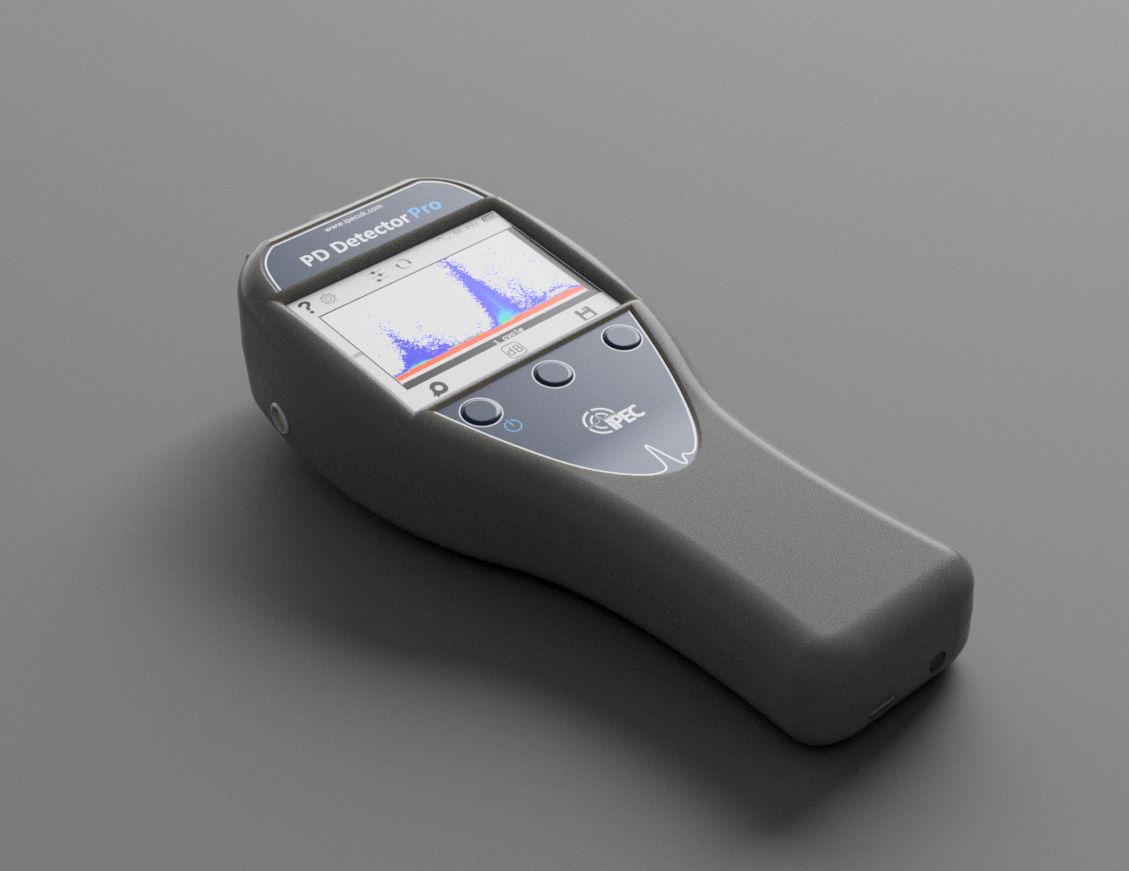

PD Detector™ Pro brings new innovation, ground-breaking functionality and advanced design to deliver a new generation in handheld PD Spot Testing. Building on IPEC's market leading technology, the PD Detector Pro brings new features to ensure the most accurate testing of your MV and HV assets.

Hear the PD

only instrument available that allows the user to hear PD activity on all sensors

PD and Noise

Advanced PD and Noise - the only device that shows you PD level and Noise Level

Multi Language

English, Arabic, Chinese, French and any other!

Wireless Sync In-built

patented in-built wireless sync to ensure PD viewed in phase with power cycle

Widescreen Colour Touchscreen

Huge high resolution display for better PD viewing

Rapidly survey the whole substation

and detect MV and HV problems before they occur

Specifications

Integrated Noise Detection Algorithm

High Resolution colour touchscreen

CC-TEV, Ultrasonic, HFCT, UHF and VDS

Audio on all sensor channels

USB-C Charging

Long Battery Life

Data Storage and PC sync

The PD Detector Pro is an efficient and easy to use tool to detect PD in MV and HV assets. Compatible with a wide range of sensors, the PD Detector Pro can be used on multiple assets to easily identify and quantify Partial Discharge.

The large colour touch screen makes analysis clear and simple and data storage with integrated software give a clear picture of asset health over time.

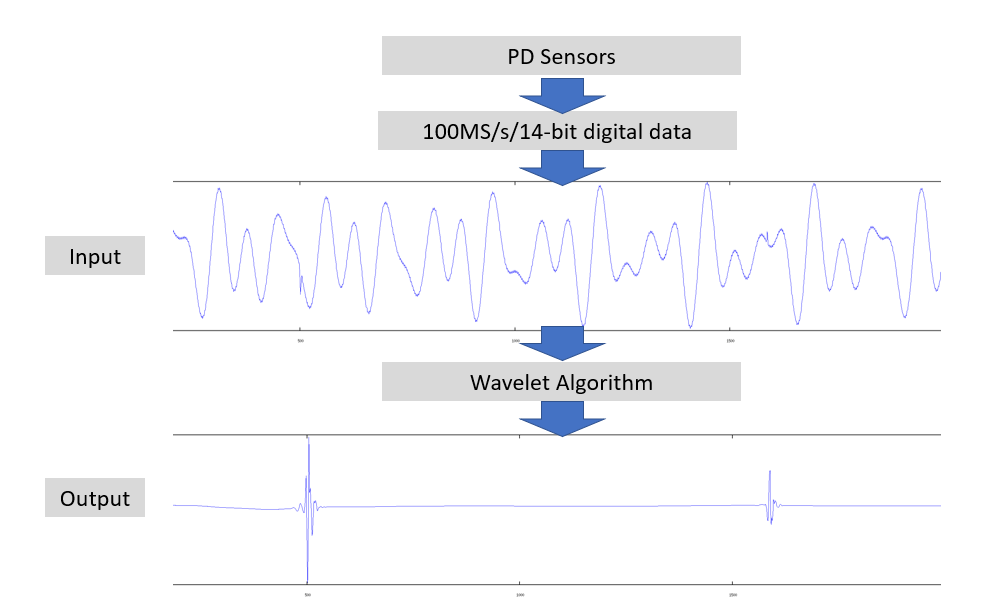

The PD Detector Pro features advanced noise rejection algorithms to effectively filter out background electrical noise, displaying both PD and Noise level for the user.

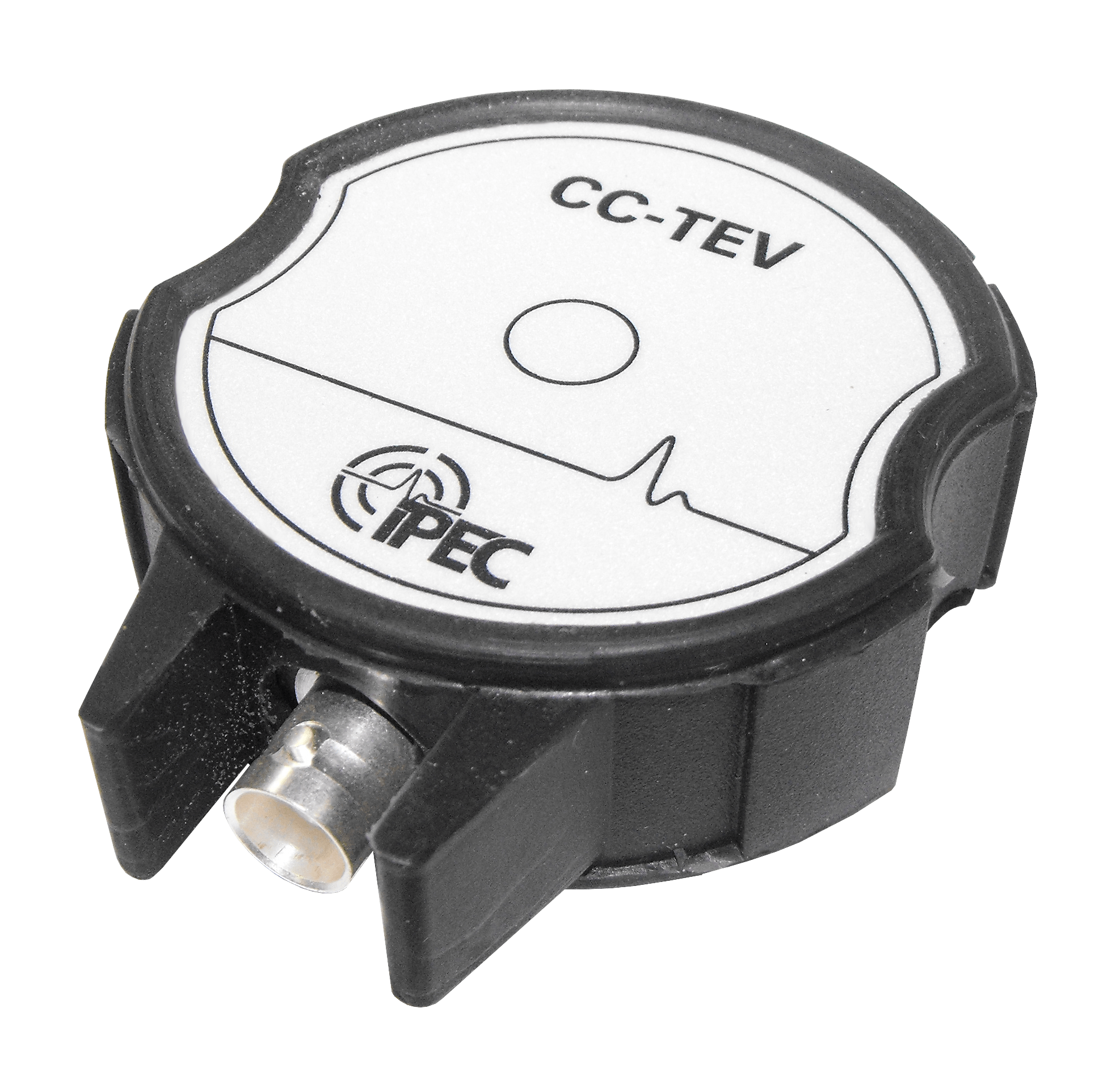

Partial Discharge activity inside metal clad high voltage plant induces small voltage impulses called Transient Earth Voltages on the surface of the metal panels. TEVs travel around the surface to the outside of the switchgear, where they can be picked up externally using the PD Detector.

Partial Discharge activity inside metal clad high voltage plant induces small voltage impulses called Transient Earth Voltages on the surface of the metal panels. TEVs travel around the surface to the outside of the switchgear, where they can be picked up externally using the PD Detector.

Defects on the surface of high voltage insulators are prone to a phenomenon known as surface tracking. Tracking causes carbon deposits that build up over time, ultimately leading to flashover and insulation failure. The PD Detector is highly sensitive to the ultrasonic emissions produced by tracking and enable the onset to be detected before insulation failure.

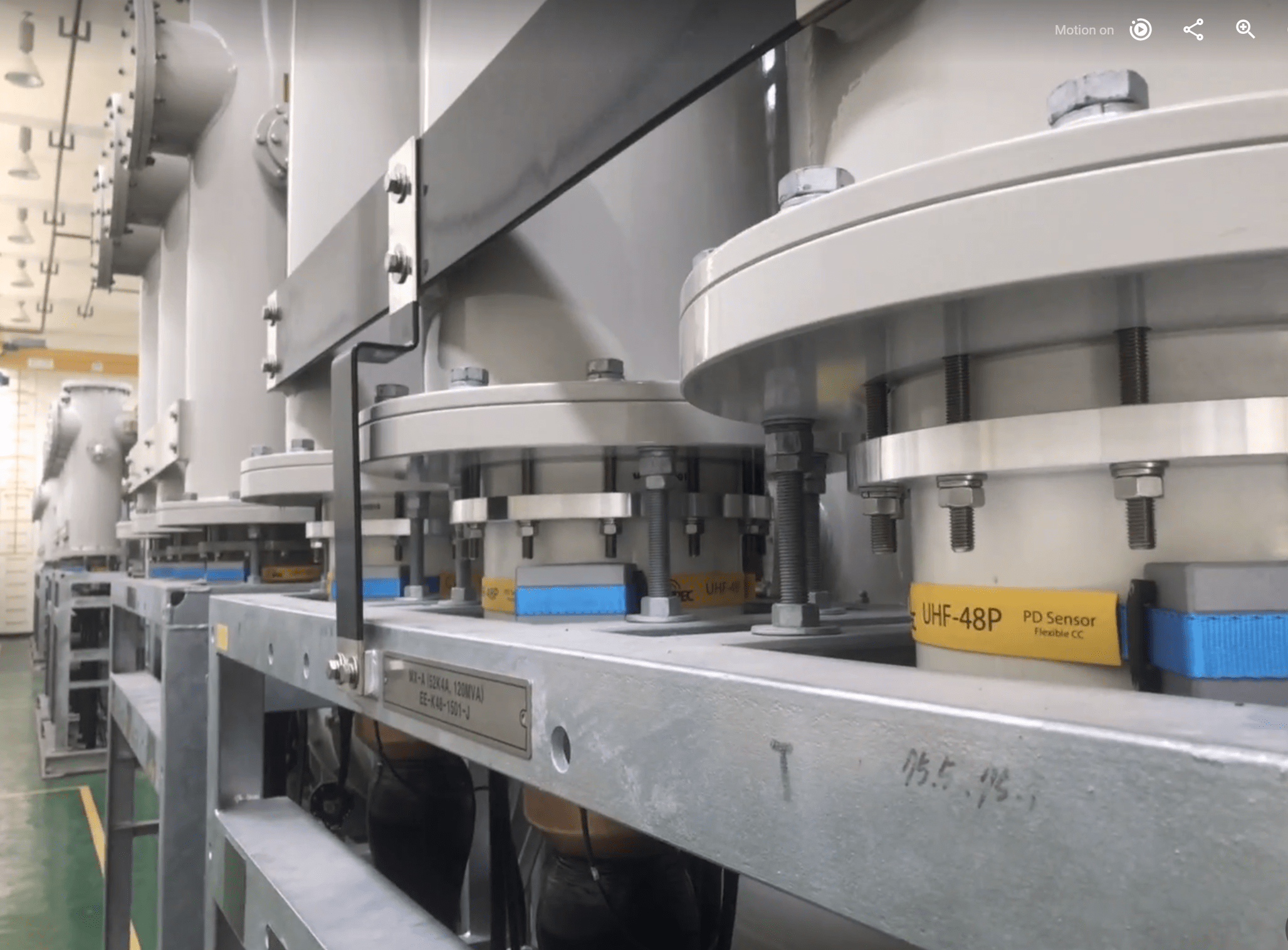

IPEC’s UHF (Ultra High Frequency) sensor is used to detect PD in EHV cable terminations, GIS (Gas Insulated Switchgear), GIL (Gas Insulated transmission Lines) & GIT (Gas Insulated Transformers). The sensors pick up signals in the UHF range (200MHz-2.0GHz) and are mounted against the insulating barrier spacers that separate components of the HV asset.

IPEC’s UHF (Ultra High Frequency) sensor is used to detect PD in EHV cable terminations, GIS (Gas Insulated Switchgear), GIL (Gas Insulated transmission Lines) & GIT (Gas Insulated Transformers). The sensors pick up signals in the UHF range (200MHz-2.0GHz) and are mounted against the insulating barrier spacers that separate components of the HV asset.

Using IPEC’s parabolic dish accessory, the test engineer can detect PD occurring on the surface of bushings and insulators in outdoor switchyards.

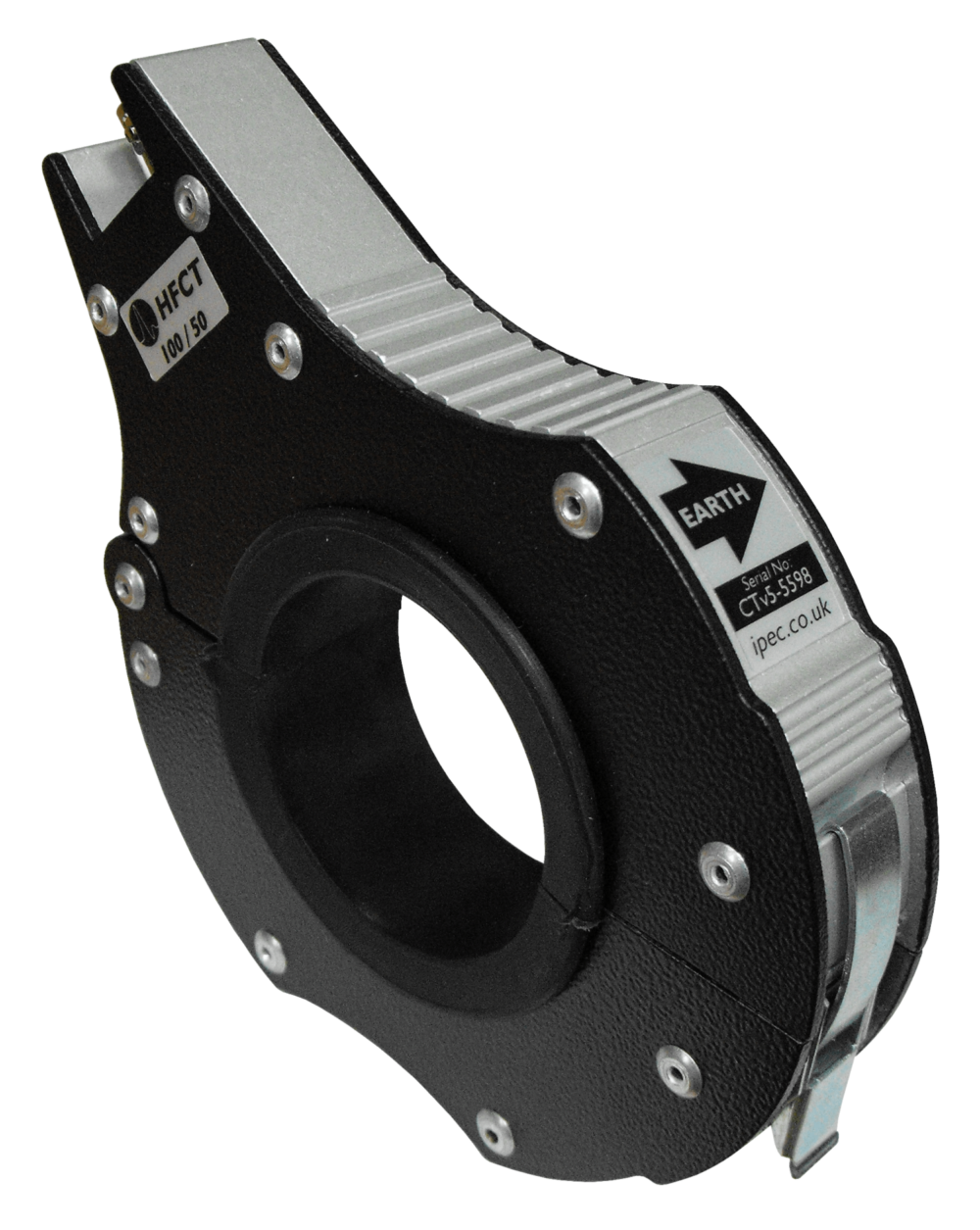

Partial discharge activity in solid high voltage insulation induces small high frequency currents in the earth conductor of the electrical system. These impulses travel along the equipment earth to the substation earth. Using a high frequency current transformer (HFCT), they can be detected as they pass through the CT.

Partial discharge activity in solid high voltage insulation induces small high frequency currents in the earth conductor of the electrical system. These impulses travel along the equipment earth to the substation earth. Using a high frequency current transformer (HFCT), they can be detected as they pass through the CT.

VDS ports are direct connections to HV cables, and cable PD can also travel and be detected at these locations. Using the VDS Sensor, it’s possible to detect these pulses.

Detection of Cable PD is more limited on handheld devices, and these should nbe used for first line detection only, primarily using PRPD and PRPS functions.